Industrial Monitoring made simple for factories.

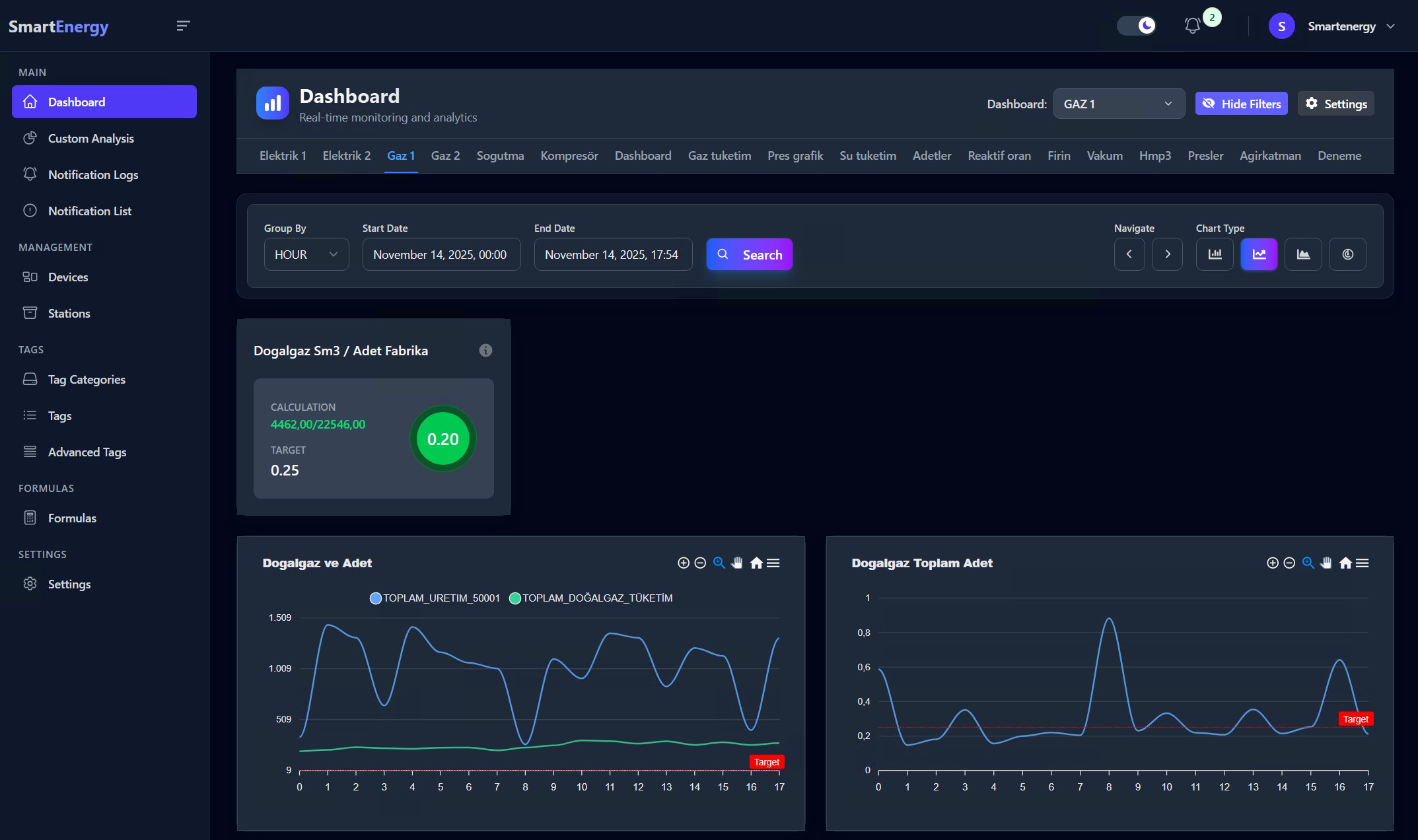

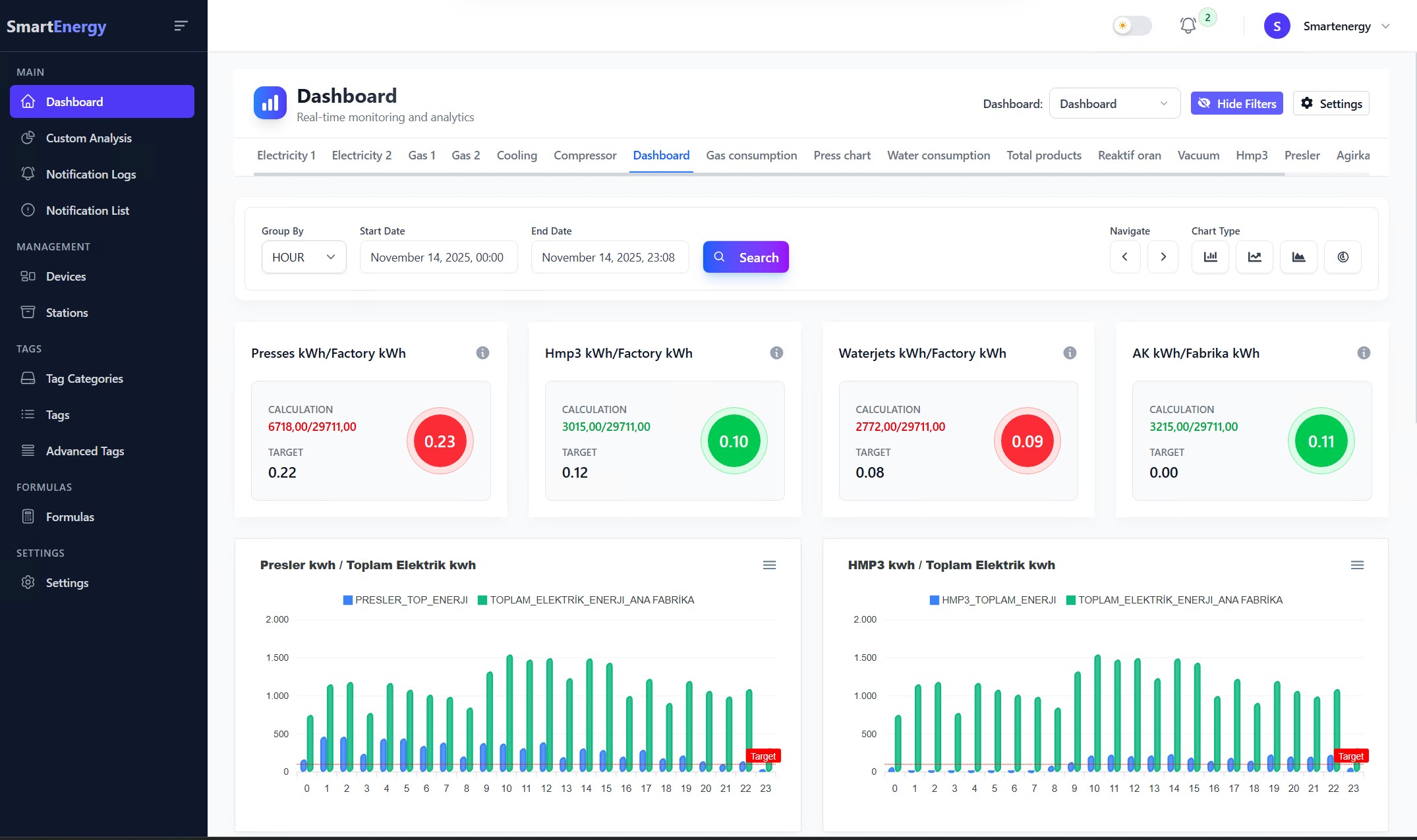

Real-time monitoring, advanced analytics, and intelligent automation for your industrial processes. Optimize efficiency, reduce costs, and gain complete visibility.

Core Features

Complete Industrial Monitoring Solution

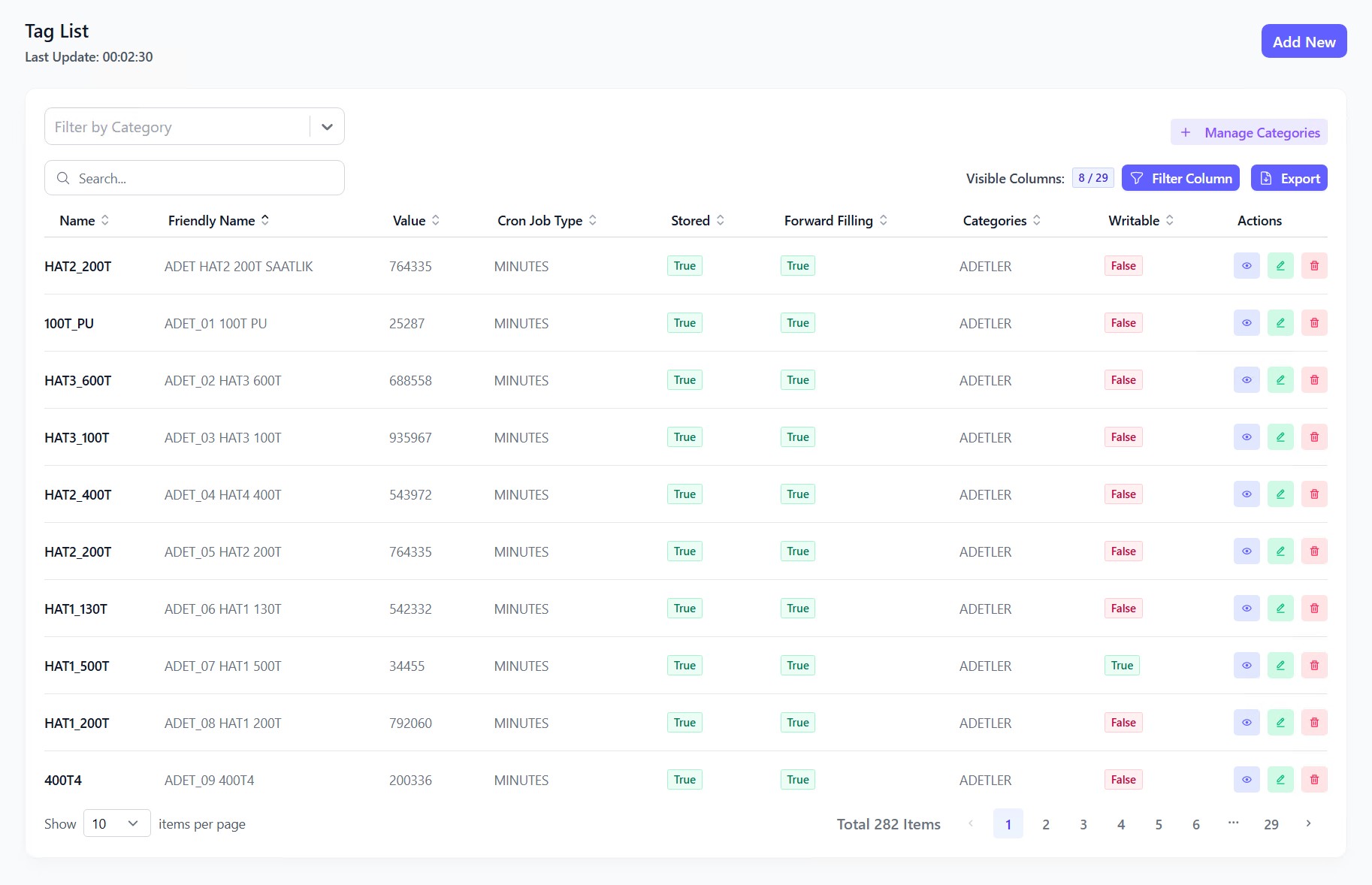

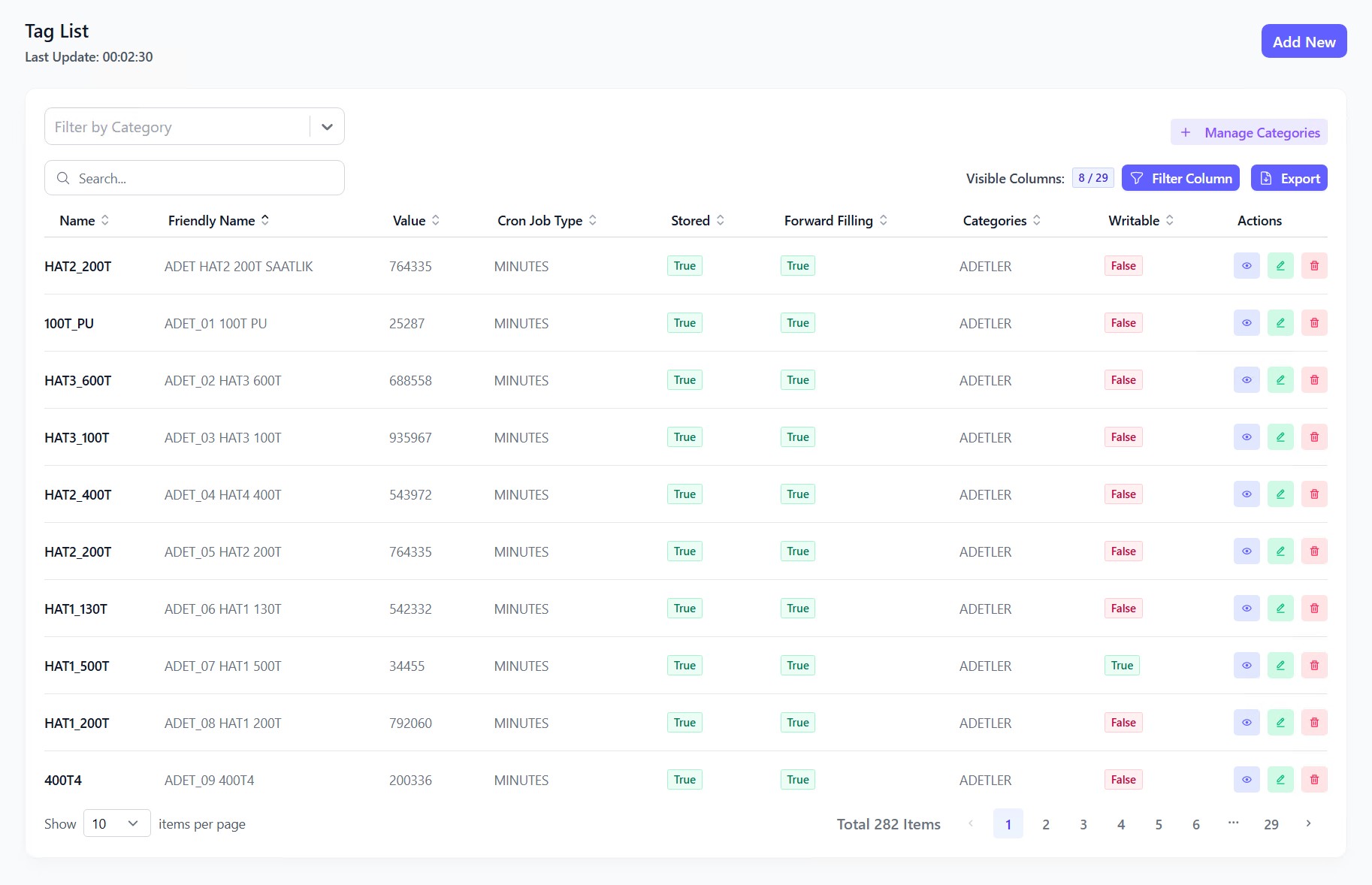

Powerful Tag Management

Organize and monitor your industrial data with advanced tagging capabilities.

Standard Tags

Real-time data monitoring from PLCs and industrial devices.

Connect to any industrial device and monitor thousands of data points in real-time. Support for Siemens, Modbus, and other major protocols.

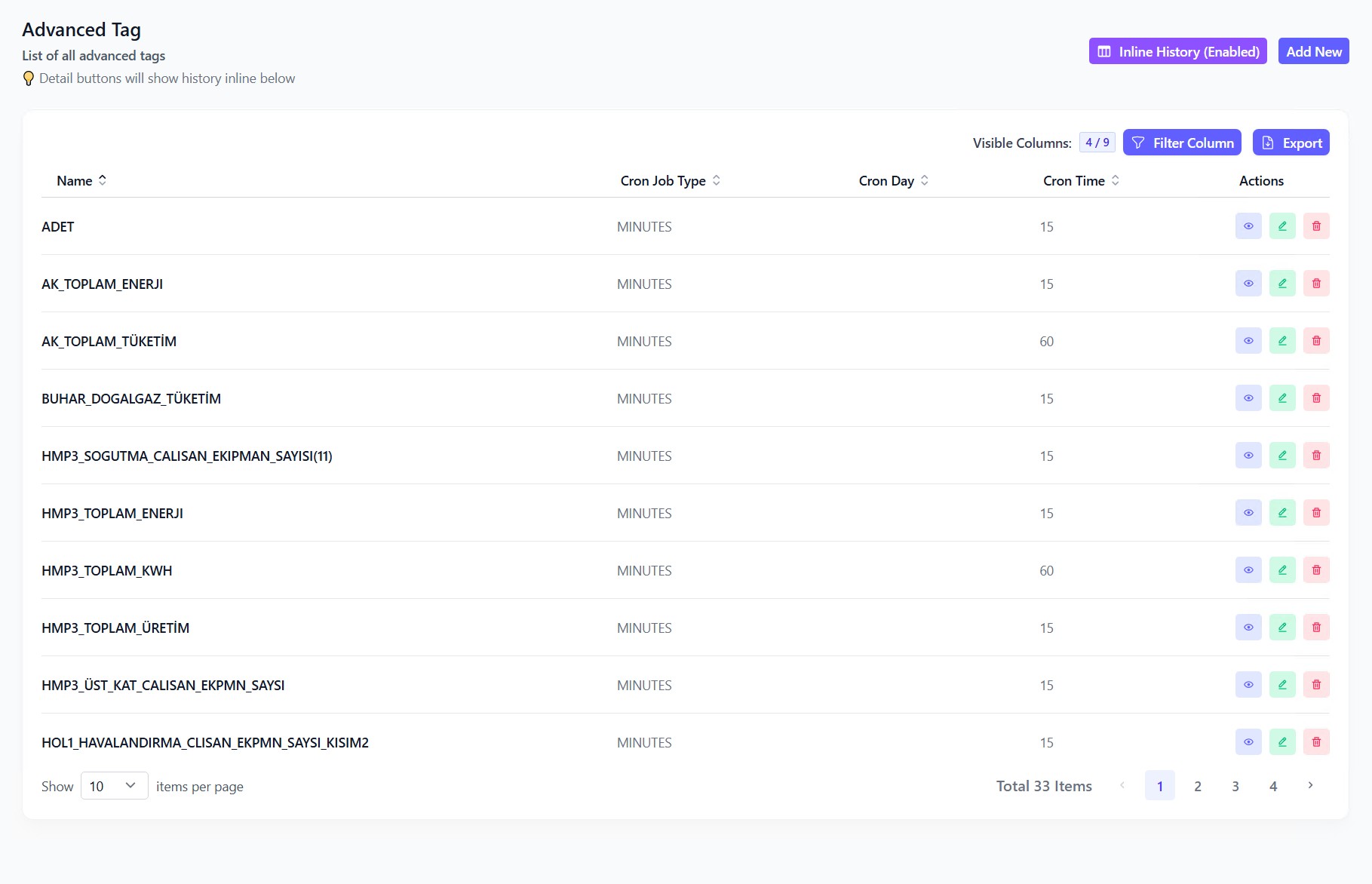

Advanced Tags

Complex calculations with multiple data sources.

Create sophisticated calculations combining multiple tags. Build custom formulas for efficiency metrics, performance indicators, and derived values.

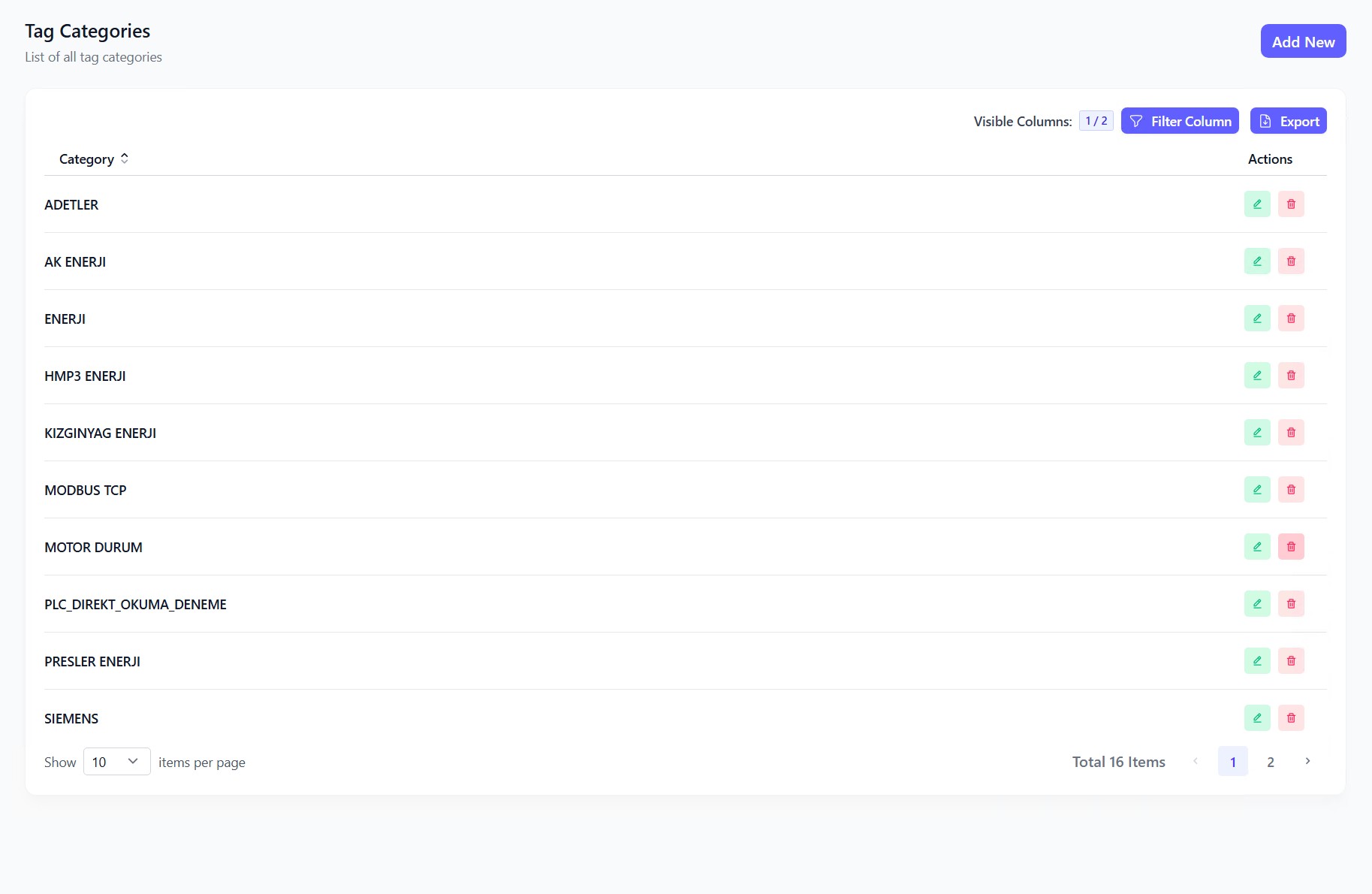

Tag Categories

Organize tags into logical hierarchical groups.

Create unlimited categories and subcategories to organize your tags. Hierarchical structure makes it easy to manage thousands of data points across complex industrial systems.

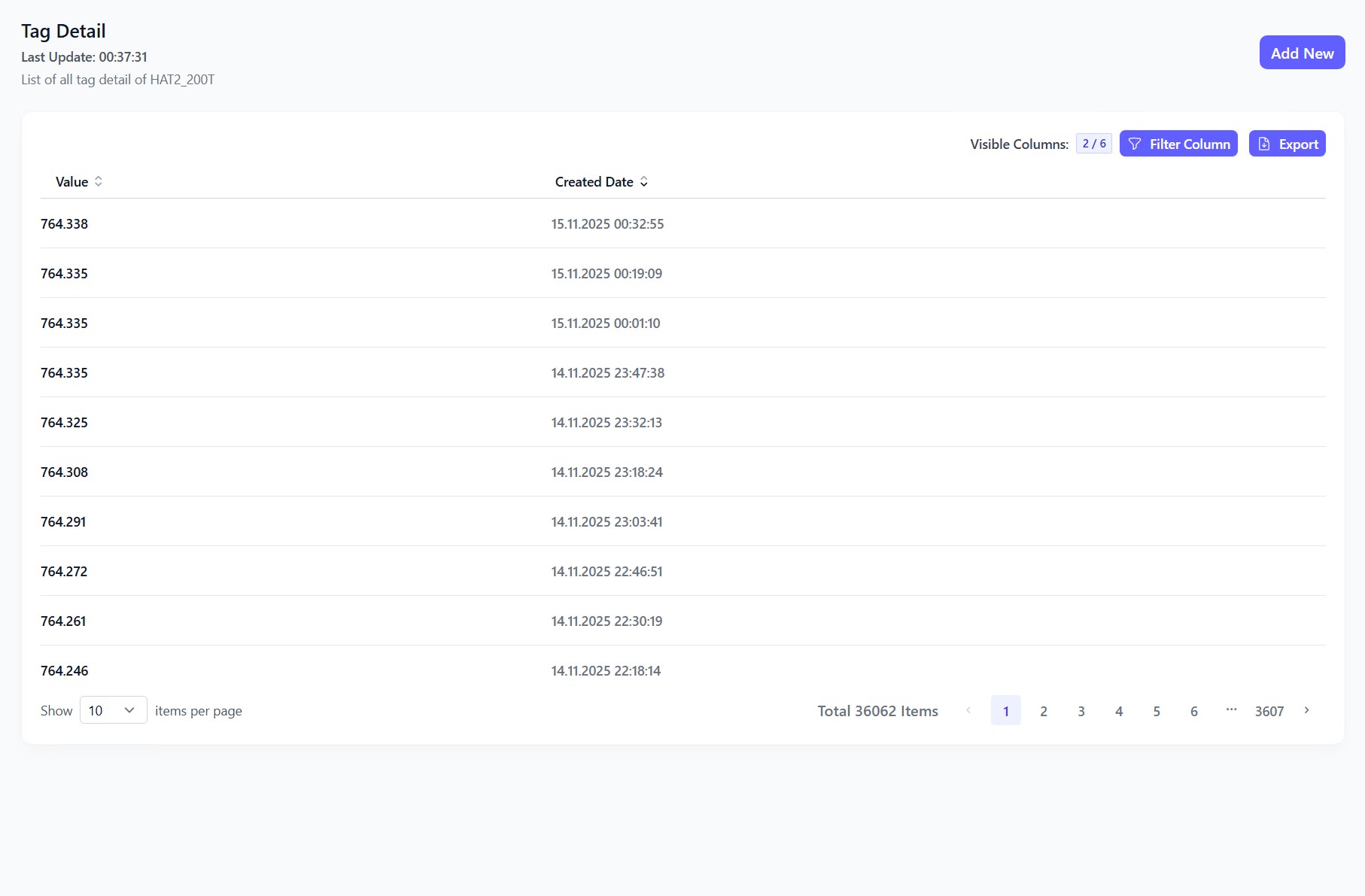

Tag History

Complete historical data tracking and analysis.

Automatic historical data logging with configurable retention. Query and analyze historical trends with powerful filtering and aggregation tools.

Real-time data monitoring from PLCs and industrial devices.

Connect to any industrial device and monitor thousands of data points in real-time. Support for Siemens, Modbus, and other major protocols.

Complex calculations with multiple data sources.

Create sophisticated calculations combining multiple tags. Build custom formulas for efficiency metrics, performance indicators, and derived values.

Organize tags into logical hierarchical groups.

Create unlimited categories and subcategories to organize your tags. Hierarchical structure makes it easy to manage thousands of data points across complex industrial systems.

Complete historical data tracking and analysis.

Automatic historical data logging with configurable retention. Query and analyze historical trends with powerful filtering and aggregation tools.

Frequently Asked Questions

Find answers to common questions about our industrial energy monitoring and automation platform.

What types of PLCs and industrial devices does Smart Energy support?

Smart Energy supports Siemens S7 series (S7-300, S7-400, S7-1200, S7-1500), Modbus TCP/IP devices, and OPC UA/DA servers. This covers the vast majority of industrial automation equipment including energy meters, temperature sensors, flow meters, pressure transmitters, motor drives, and building automation systems.

How long does it take to implement Smart Energy in our facility?

Typical implementation takes 3-10 days from start to full automation. This includes discovery and planning (1 day), device configuration (1-2 days), dashboard setup (1-2 days), formula development (2-3 days), and training (1-2 days). No hardware installation is required as we connect to your existing PLCs.

Do we need to install additional hardware or modify our existing PLCs?

No additional hardware installation is required. Smart Energy connects to your existing PLCs and industrial devices over your network. We don't modify your PLC programs or require any changes to your current automation setup. The system works alongside your existing infrastructure.

How does the automatic intervention system work?

Our formula-based automation engine allows you to create rules using a visual builder without coding. For example, you can automatically shut down compressors when production stops, adjust HVAC based on occupancy, or reduce equipment speed during off-peak hours. Formulas can be tested in safe mode (notification-only) before activating automatic interventions.

What kind of energy savings can we expect?

While results vary by facility, our customers typically achieve significant energy cost reductions within 6-12 months. Common savings come from eliminating off-hours consumption, optimizing equipment operation, reducing peak demand charges, and identifying inefficient processes. Many facilities see payback periods of 4-6 months.

Can multiple users access the system with different permission levels?

Yes, Smart Energy supports multi users with role-based access control. Each user can create their own personalized dashboards, set custom notification preferences, and access features based on their role. Administrators have full control over system settings.

How is historical data stored and for how long?

All TAG data is automatically recorded to the database based on configurable schedules (from 1 second to monthly intervals). Historical data retention is configurable based on your needs and storage capacity. The system includes powerful query tools for analyzing historical trends and generating reports.

What happens if the network connection to a PLC is lost?

Smart Energy includes automatic connection recovery and error handling. If a connection is lost, the system continuously attempts to reconnect and logs all connection events. Forward filling ensures data continuity for meter readings. You'll receive notifications about connection issues and can view detailed logs.

Can we export data for external analysis or reporting?

Yes, all data can be exported in multiple formats including Excel, CSV, and JSON. Export functionality is available throughout the system on listing pages, dashboards, and analysis views. You can also integrate with other business intelligence tools using our API.

How do COST cards help with energy management?

COST cards provide real-time cost calculations based on energy consumption, production output, and resource utilization. You can set targets and receive color-coded alerts when costs exceed thresholds. This enables immediate visibility into cost per unit produced, helping identify inefficiencies and optimize operations.

Is training required to use the formula builder?

The formula builder is designed to be intuitive and doesn't require programming knowledge. We provide comprehensive documentation and training during implementation. Most users can create basic formulas within hours of training. Complex automation rules may require more experience, but our support team is always available to help.